Toronto: mass concrete and high performance mix design on CIBC Towers

Long, unpredictable transit times and locally produced high-temperature cement presented challenges for constructing two center core structure towers in Toronto.

Atlanta Mass Concrete: Speeding Up Production Rates

In 2020 in Atlanta, faster pour times and the more consistent mix led to significant cost-savings for both the Ready Mix Producer and the Contractor.

Six-Figure Savings by Eliminating Concrete Cooling Tubes on Harbor Bridge

Corpus Christi's iconic Harbor Bridge required mass concrete for 500-foot tall towers. High humidity and ambient temperature required extreme temperature control to avoid complications with the concrete in the forms. NITROcrete™ enabled the project to meet temperature specifications without concrete cooling tubes, saving time and expense.

I-74 Mississippi Bridge: Lower temperature delivered over 36+ hour pours

When a previous liquid nitrogen application over-promised & under-delivered, NITROcrete™ temperature control experts met rigorous temperature specifications, on schedule.

Cryogenic Industrial Solutions acquires NITROcrete, expanding offerings with new technology

Cryogenic Industrial Solutions (CIS), a leading provider of cryogenic transport trailers, tanks, equipment repairs, lease fleet and nitrogen services, announced the acquisition of NITROcrete earlier this month. NITROcrete joins Alloy Custom Products, WesMor Cryogenics, CIS Leasing and Integrity Gas Services under the CIS umbrella of companies.

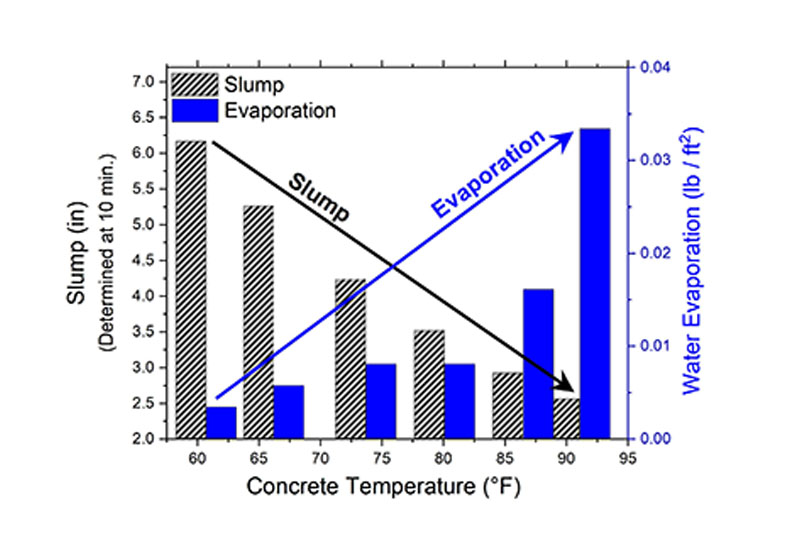

Workability, Evaporation, and Concrete Temperature | NITROcrete

Hot weather concreting isn't for the faint of heart. We'd hazard a hypothesis that profanity on project sites goes up proportionally with ambient temperature. In short: hot weather concrete is difficult. A simple-sounding yet familiar problem, but one with a complicated explanation. Stubborn hot weather concrete causes challenges for a variety of interconnected reasons.

ADOT changes specification to include liquid nitrogen

“We often receive questions about the effects of liquid nitrogen on aggregates,” said Eric Van Dixhorn, NITROcrete VP of Engineering. “Arizona was invested in confirming the safety of pre-cooling methods of delivering liquid nitrogen to the aggregate — which differs from what people historically think of when they imagine LN for concrete cooling...

Reduce Carbon Emissions and Waste

A third-party Streamlined Comparative Life Cycle Assesment compared liquid nitrogen cooling with ice cooling; the results showed significant reduction in carbon emissions, harmful particulate matter, and energy consumption.

Stabilize Hydration Rate

Lower temperatures yield more ideal hydration for stronger concrete, among other benefits.

Reduce Plastic Shrinkage Cracking

NITROcrete™ helps control evaporation rate, reducing shrinkage cracking. By controlling temperature, year-round problems with plastic shrinkage are mitigated when...