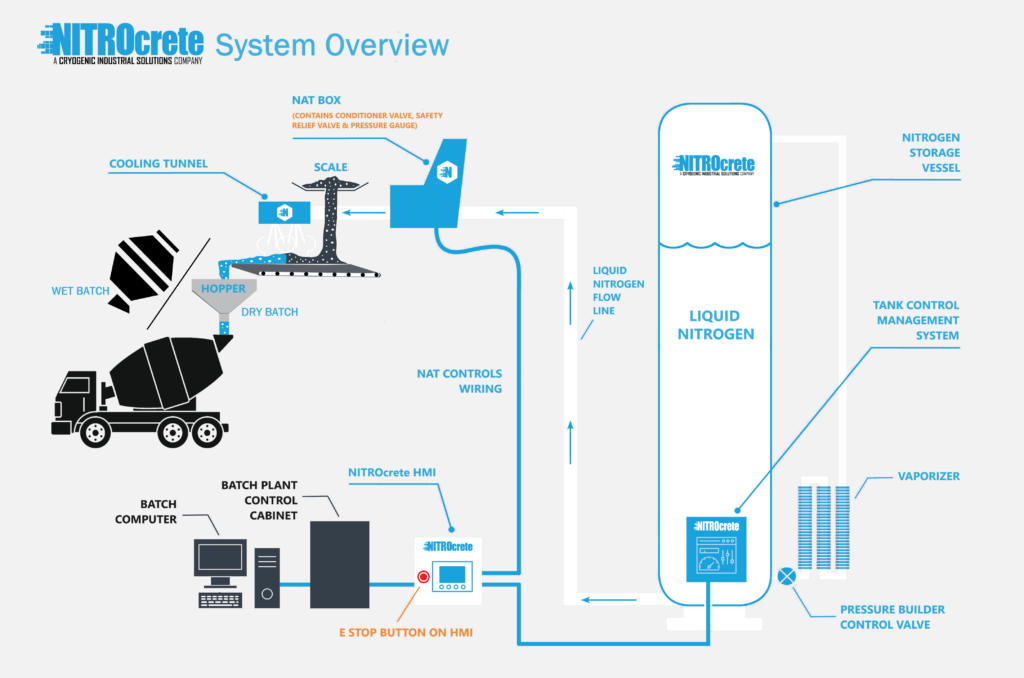

Concrete Temperature Control System

Comprehensive Concrete Temperature Control Systems

With NITROcrete™ our industry partners have

even in hot weather concreting

in the six figure range

in a fraction of the time

temperature specifications

Advantages

the batching process to eliminate delays

temperature control

and software integration

Why use liquid

nitrogen to temperature control concrete?

With temperature-controlled concrete systems, our customers:

Enhanced set time • Easier finishing

NITROcrete™ improves workability for easier finishing and improved slump life. Most people in the concrete industry know that higher concrete temperatures lead to reduced finishability, lower slump, and increased effort for a quality surface finish.

Using NITROcrete™ as an admixture for temperature control improves the fresh qualities of concrete — no matter the weather or transit time.

Control Evaporation Rate • Prevent Shrinkage Cracking

Shrinkage cracks appear when the evaporation rate on concrete surface is greater than the rate at which bleed water rises to the surface

Outside of delaying concrete pours or rescheduling crews, few practical options exist to control evaporation. However, NITROcrete™ offers a way to control temperature, thereby managing evaporation rate to prevent shrinkage cracking.

Improve Strength • Hold Temperature Lower, Longer

Hydration rate and temperature are closely related. Lower temperatures yield more ideal hydration for stronger concrete that’s easier to work with.

By lowering temperature, NITROcrete™ slows the rate of hydration; at the cement grain-level, this slower hydration rate introduces more uniformity, which protects concrete from early-age shrinkage and cracking.

Ambient Temperature Change • Traffic in Transit

Conditions onsite change moment-to-moment. Whether that’s ambient temperature or traffic during transit, NITROcrete™ helps hedge against unpredictable variables that can wreak havoc on project timelines.

By offering more comprehensive cooling without downtime, projects are protected when the inevitable chaos of transit or weather threaten to stall progress.

Reduce Energy Consumption • Meet Specification

Reduce waste during production. Reduce the overall impact of concrete production by mitigating waste, preventing lost loads, and reducing carbon emissions.

As the industry seeks out change at every operational level to improve sustainability, NITROcrete adds to their efforts by removing ice and, instead, introducing a temperature control process that reduces emissions and energy consumption.