Project Overview

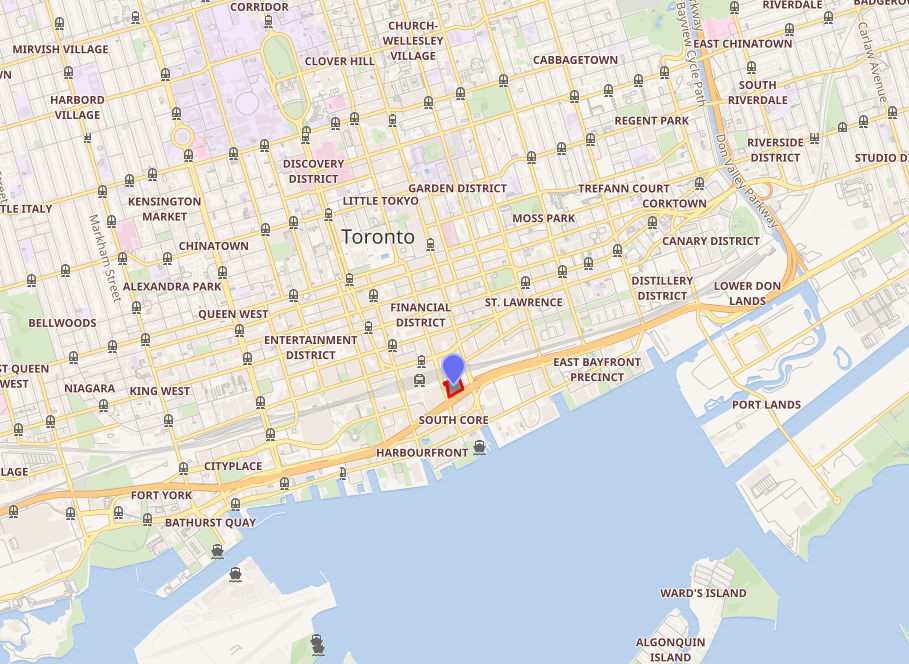

In Toronto’s busy financial district, NITROcrete™ managed temperature for high performance, mass From 2017-2025, in the heart of Toronto’s financial district, two cutting-edge office towers were built within a massive 3-million-square-foot architectural complex—CIBC Square. Featuring iconic 49- and 50-story glass buildings, the towers are connected by a one-acre elevated park that spans the city’s rail corridor.

The first tower, located at 81 Bay Street, opened in 2020, and the second tower was completed in 2025. The Canadian Imperial Bank of Commerce (CIBC) is the primary tenant of both towers, with additional space for retail businesses.

This ambitious project is a joint venture between Ivanhoé Cambridge and Hines, with EllisDon serving as the general contractor. The development is targeting LEED Platinum certification, aiming for maximum energy efficiency and state-of-the-art infrastructure.

The Challenge

Constructing two center-core wall structure towers in a dense urban environment presented multiple challenges:

- Minimizing impact on downtown businesses, traffic flow, nearby stadiums, and public activities.

- Strict temperature control requirements: concrete temperatures could not exceed 25˚C (77˚F).

- Locally sourced cementitious materials caused abnormally high temperatures at the batch plant.

- Long transit times in congested and unpredictable city traffic further complicated temperature maintenance.

- Use of mass concrete elements required additional care to maintain specification compliance.

To overcome these challenges and meet the rigorous LEED standards, the concrete mix used in construction of the first tower would not only have to be efficiently and substantially cooled, but it would have to remain so under unpredictable external conditions, including traffic delays and temperature spikes. Moreover, serious project delays and costs would be incurred if any of the batches were rejected due to temperature.

The Solution: NITROcrete

To meet the demanding thermal and performance requirements of the first CIBC tower project, traditional cooling methods were not sufficient.

NITROcrete offered a unique solution:

- Effectively reduced and controlled concrete temperatures.

- Maintained consistent temperatures from batch plant to job site.

- Provided longer-duration temperature holding compared to other cooling methods.

- Ensured delivery of in-spec concrete despite traffic delays and logistical variability.

- Supported a high-performance mix design of 80 MPa / 11,500 psi with high cement and low water content.

Results: Perfectly Cooled Concrete

With NITROcrete’s solutions in place, the CIBC project reported zero concrete loads rejected.

Despite the large number of variables in play, NITROcrete concrete was the same temperature at the job site as at the batch plant. NITROcrete played a pivotal role in the success of the CIBC Square project by delivering reliable concrete temperature control in a high-stakes, high-performance urban construction environment.

As a result, the project was able to move forward in a timely manner, without incurring additional delays. Importantly, traditional concrete cooling and transportation methods would not have brought about this result, which is why NITROcrete is the preferred choice for high-stakes construction projects around the world. Contact us today to learn more about NITROcrete’s applications in large-scale construction!

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind. Learn more or reach a sales rep today!