Concrete workability, evaporation rate, and hot weather concreting

November 8, 2020 | Eric Van Dixhorn, Laura Price Hall, Cameron Wilson

Hot weather concreting isn’t for the faint of heart. We’d hazard a hypothesis that profanity on project sites goes up proportionally with ambient temperature. In short: hot weather concrete is difficult. A simple-sounding yet familiar problem, but one with a complicated explanation. Stubborn hot weather concrete causes challenges for a variety of interconnected reasons.

NITROcrete R&D has been researching those reasons and their effects, if only to provide a more accurate metric than profanity to gauge why hot weather concreting is so challenging.

The ACI Committee 305 Guide to Hot Weather Concreting explains many of these challenges; however, we were curious to dig more deeply into the following questions:

- What factors contribute to poor workability with fresh concrete?

- What are the connections between slump loss and temperature?

- And how does the rate of evaporation affect workability? (And furthermore, what methods do we have available to test for otherwise relatively subjective qualities like finishability?)

Slump Loss and Workability in Practice

In hot weather conditions, fresh concrete experiences a higher rate of slump loss, which leads to difficulty placing and achieving the desired finish. Slump loss costs time and labor for the concrete placement contractor, whose team then has to fight with concrete that’s challenging to finish. To mitigate, there’s an impulse to add water at the jobsite. While common practice, and perhaps not detrimental under some conditions, the additional water can negatively impact the strength, durability, and serviceability of the finished product. If adding water isn’t the best option to improve workability, then what root causes of poor workability and slump loss can we address, instead?

What Our Intuition Gets Wrong: How Temperature Affects Fresh Concrete

If we think of fresh concrete like other fluids or soft solids, we might incorrectly expect that higher temperatures make concrete easier to work with*. Think: butter spread on warm toast, raw honey scooped into tea, or hydraulic fluid that flows more readily when it’s heated. It’s “melty” to be unscientific. Higher slump, to be more precise.

(*Note: As evidenced by aforementioned profanity, no one who’s worked with concrete during summer would actually suggest that hot weather makes concrete easier to work with. However, we draw this comparison to illustrate why concrete behaves differently than we might expect if we assume it behaves like other soft solids.)

We don’t see the same “melty” behavior from concrete when it’s exposed to higher temperature during mixing. What accounts for this difference? Unlike many soft solids or fluids (like the butter, honey, or hydraulic fluid mentioned above), concrete becomes less workable as temperature increases. But why is that? We must dig deeper to understand what causes the slump loss.

Getting Beyond Presuppositions: Evaporation Rate

To further uncover the factors that contribute to slump loss, we must also consider water — specifically, water as it relates to evaporation rate. The water in the concrete evaporates at substantially different rates depending on the concrete’s temperature (with higher temperatures, more evaporation occurs). With that, higher evaporation rates cause greater slump loss.

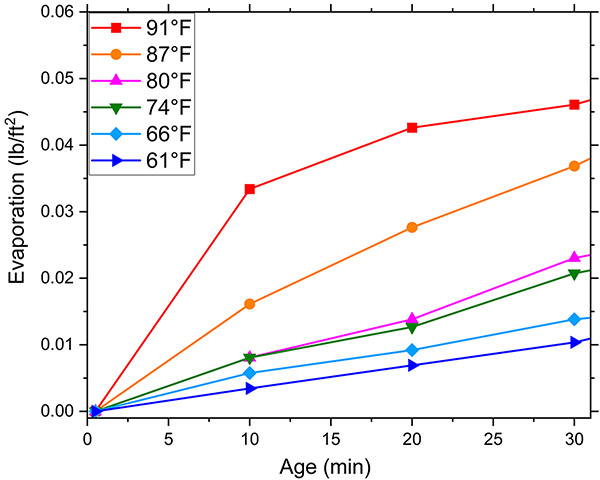

Thankfully, evaporation rates are well documented and relatively well understood. The ACI 305R-99 guide explains that evaporation rates will increase as the temperature increases. Figure 1 below shows that evaporation during batching is directly related to slump loss. As evaporation increases, slump decreases. This slump loss raises concerns about plastic shrinkage cracking, increased permeability, and long-term durability.

The data shown below in Figure 1 indicate that significant evaporation of water takes place during the initial mixing process. Our measurements here show the amount of evaporation from concrete samples batched at different temperatures.

(*Note: As evidenced by aforementioned profanity, no one who’s worked with concrete during summer would actually suggest that hot weather makes concrete easier to work with. However, we draw this comparison to illustrate why concrete behaves differently than we might expect if we assume it behaves like other soft solids.)

We don’t see the same “melty” behavior from concrete when it’s exposed to higher temperature during mixing. What accounts for this difference? Unlike many soft solids or fluids (like the butter, honey, or hydraulic fluid mentioned above), concrete becomes less workable as temperature increases. But why is that? We must dig deeper to understand what causes the slump loss.

Figure 1: Evaporation Rate and Temperature After Initial Mixing

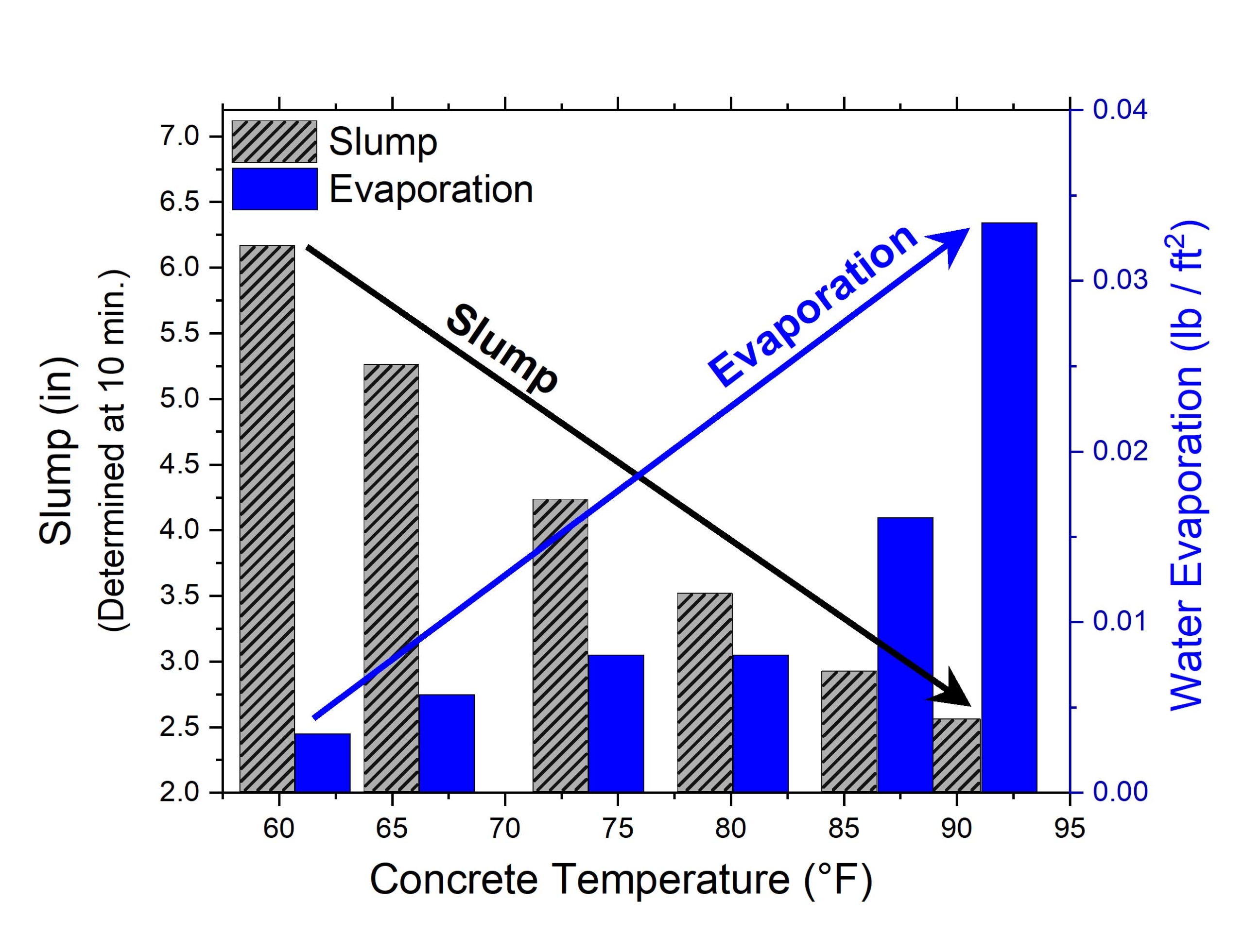

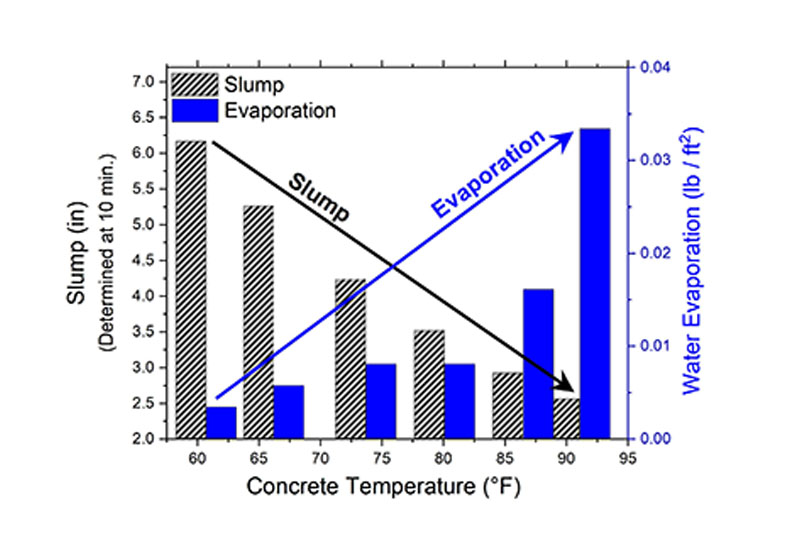

Research from the Portland Cement Association and Bureau of Reclamation have shown that concrete’s rheological properties (namely slump) are affected by the concrete’s initial temperature. The data collected from NITROcrete in Figure 2 supports this information.

Figure 2: Slump, Evaporation, and Temperature

Summary

- Increased evaporation rate leads to slump loss

- Evaporation rate after initial mixing increases with higher temperature concrete

- Lower concrete temperature reduces slump loss, improving workability

- Workability improves for easier placing and finishing

- NITROcrete cools without changing water content

The data above indicates that higher concrete temperatures lead to higher evaporation rates. Higher evaporation rates then result in a lower initial slump, and furthermore, a higher rate of slump loss during the mixing and placing process.

Conclusion

While explaining poor workability depends on addressing complex, interconnected reasons, the effects of unworkable concrete are simple: frustrated teams, cursing the weather, or “blessing” the concrete with water that can cause plastic shrinkage cracking. By using temperature control to reduce slump loss, workability increases — and so does team morale, even in on the hottest [profanity omitted] days of the year.

References

American Concrete Institute (1999) “Guide to hot weather concreting,” ACI 305R-99.

Burg, R. (1996) “The influence of casting and curing temperature on the properties of fresh and hardened concrete,” Portland Cement Association, Research and Development Bulletin RD113T.

Last updated: November 9, 2020 at 4:05 pm MST

Due to continued product research and development, the information herein is subject to change without notification. Details of this Technical Sheet are believed to be accurate at time of publication.

Eric Van Dixhorn

Eric Van Dixhorn, VP of Engineering and R&D at NITROcrete, is a civil engineer with expertise in concrete temperature control, project management, and design engineering. He has extensive experience providing quality control and temperature specification development for large-scale infrastructure projects throughout the United States and Canada.

Laura Price Hall

Laura Price Hall is a technical communications specialist and marketing communications manager at NITROcrete. She has an M.A. in Rhetoric and Composition from Colorado State University. She researches technical communication, digital rhetoric, and learning & development.

Cameron Wilson

Cameron Wilson, R&D Engineer at NITROcrete, is a civil engineer with an expertise in concrete materials science. He has an M.S. in Civil Engineering from Oregon State University. His research includes early age concrete hydration, internal curing, and super absorbent polymers.

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.