Reduce CO2 emissions, energy consumption, and harmful particulate matter

When compared to ice cooling, cooling concrete through automation with liquid nitrogen affords advantages through eliminating waste and streamlining production.

- By meeting temperature specification, concrete avoids wasted loads, thereby avoiding the subsequent wasted energy consumed during production.

- By cooling during batching, NITROcrete streamlines production to avoid excess emissions required for cooling with ice or other methods.

Comparative Streamline Lifecycle Analysis

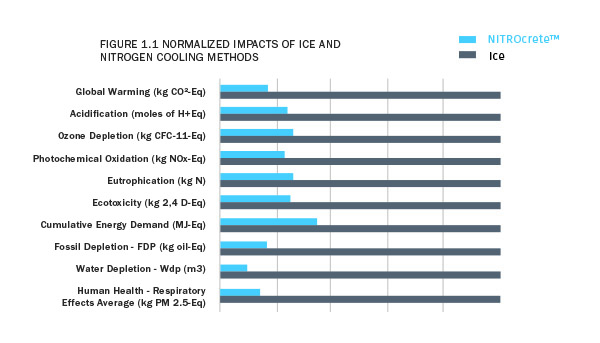

John Beath Environmental, LLC (JBE), an environmental compliance and sustainability consulting agency, conducted a comparative Life-Cycle Analysis for NITROcrete™ liquid nitrogen (LN) cooling vs. ice. The study measured for environmental impact categories such as CO2 emissions, energy consumption, and particulate matter.

Conclusion

JBE found that “NITROcrete performs better for relevant impact categories like energy usage, global warming, and respiratory effects in humans.”¹

References

¹ John Beath Environmental. “Streamlined comparative life cycle assessment for NITROcrete process.” 2019

Last updated: October 13, 2020 at 2:48pm MT

Due to continued product research and development, the information herein is subject to change without notification. Details of this Technical Sheet are believed to be accurate at time of publication.

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.