Natural Hydration Stabilizer

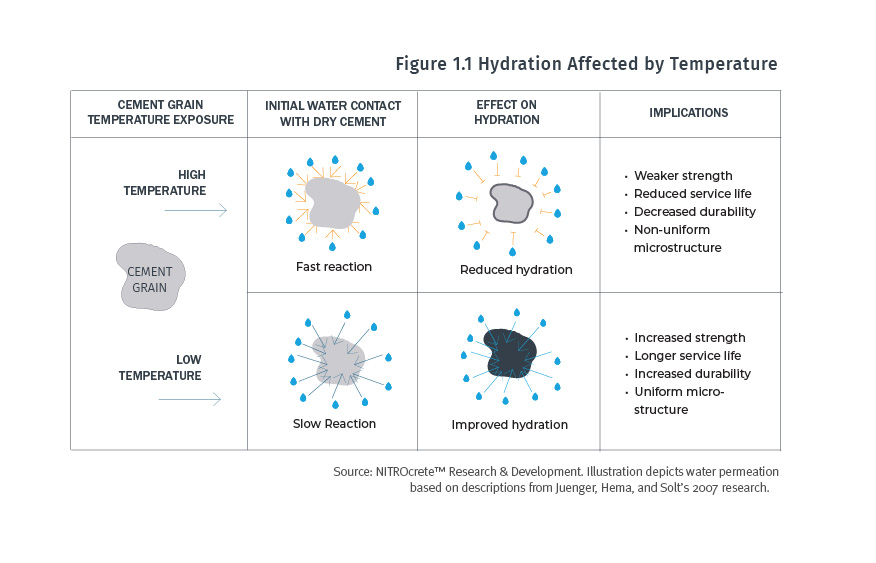

Hydration rate and temperature are closely related. Lower temperatures yield more ideal hydration for stronger concrete that’s easier to work with.1

By lowering temperature, NITROcrete™ slows the rate of hydration; at the cement grain-level, this slower hydration rate introduces more uniformity.2 This cohesion improves durability, as the resulting concrete is less permeable.

Hold Temperature Cooler, Longer

Field experience has shown NITROcrete can provide a ‘lower and hold’ effect on concrete temperature.3 This longer temperature reduction comes, in part, from lowering the heat generated during hydration.4

Research shows that when comparing higher vs. lower temperature mixes, the heat generation rate is higher and occurs more quickly when compared to heat generation from lower temperature mixes.5 In lower mix temperature, heat generation is reducted and occurs over a longer time period.

Conclusion

Holding temperature lower for longer means concrete remains easier to work with for longer, with better slump retention and improved workability.

References

1 Juenger, M., J. Hema, and S. Solt. (2007). The effects of liquid nitrogen on concrete properties, Center for Transportation Research, University of Texas at Austin, FHWA/TX- 08/0-5111-1.

2 ibid.

3 Van Dixhorn, et. al. (2018) Cooling aggregate with liquid nitrogen to control concrete temperature, NITROcrete Research and Development.

4 Ježo, L. et. al. (2010) Effect of temperature upon the strength development rate and upon the hydration kinetics of cements, Ceramics – Silikáty, 54 (3), pp. 269–276

5 ibid.

About NITROcrete™

NITROcrete is the world leader in concrete temperature control solutions. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides comprehensive concrete cooling automation, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.