Arizona Department of Transportation changes concrete specification to permit aggregate cooling with liquid nitrogen

NOVEMBER 4, 2020 | FORT COLLINS, COLORADO

- ADOT agreed with extensive petrographic examination results that showed the liquid nitrogen does no harm to coarse or fine aggregates

- Customers interested in efficient concrete road and infrastructure work can use NITROcrete with the confidence of its full approval by ADOT for road work

In mid-July, the Arizona Department of Transportation announced their revised specifications for hot weather concreting. These new specifications allow the use of liquid nitrogen to cool aggregate for concrete construction. After collaborating with NITROcrete, area producers and third-party testing agencies, this specification development reflects the extensive research and testing that proves NITROcrete’s automated method for delivering liquid nitrogen is safe for use on aggregate.

“We often receive questions about the effects of liquid nitrogen on aggregates,” said Eric Van Dixhorn, NITROcrete VP of Engineering. “Arizona was invested in confirming the safety of pre-cooling methods of delivering liquid nitrogen to the aggregate — which differs from what people historically think of when they imagine LN for concrete cooling. Older LN methods deliver liquid nitrogen in the back of the ready-mix truck after the initial mixing. NITROcrete uses a different technology. After rigorous examination, which included various ASTM aggregate tests and petrographic examination, ADOT agreed with the test results that showed the liquid nitrogen does no harm to coarse or fine aggregates,” Van Dixhorn said.

The results of third-party testing confirm that liquid nitrogen delivered with NITROcrete’s system is safe for aggregates. Furthermore, ADOT’s decision to change their specification based on this research opens up possibilities for more cost-effective, safer concrete temperature control for Arizona’s road work operations, especially during hot weather concreting.

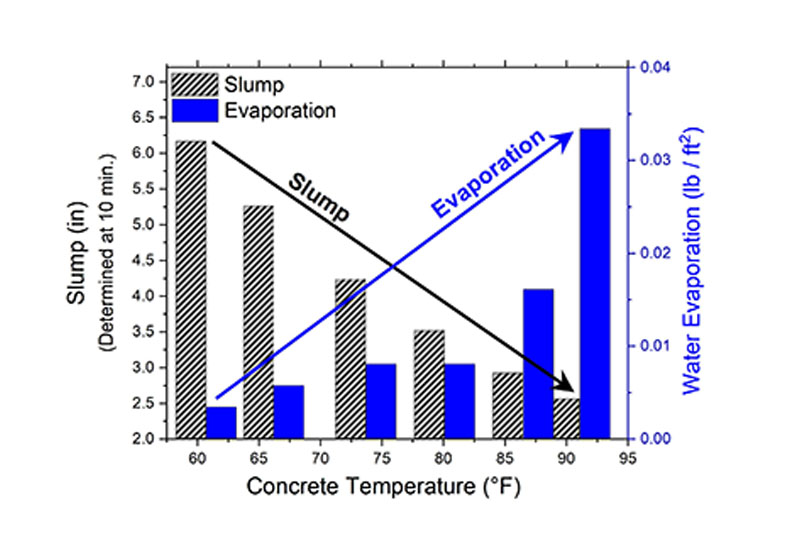

“Arizona’s blazing summer temperatures pose extreme challenges for concrete producers. Hot weather concreting can cause problems with placement, workability, and tends to affect the overall quality of the concrete. NITROcrete offers a solution to these obstacles delivering a more efficient process, reducing labor intensity and safety incidents, resulting in cost savings,” said Dan Doerrfeld, NITROcrete VP of North America West. “We’re grateful that more customers interested in efficient concrete road and infrastructure work can use NITROcrete with the confidence of its full approval by ADOT,” Doerrfeld said.

While hot weather concreting in places like Arizona benefit from temperature control, NITROcrete is used in mass concrete throughout the year as well. “This year, we expect that our systems in Canada will see a good deal of use, even throughout the fall season,” said Van Dixhorn. The same aggregate cooling technology that enables easier placement and finishing during high ambient temperatures also provides an innovative solution for reliable thermal control in mass concrete. With that, NITROcrete offers concrete cooling solutions for a variety of projects and regions, both internationally and in the United States.

Arizona joins a host of other US states who have approved liquid nitrogen with NITROcrete for concrete operations. As new concrete technologies emerge, states like Arizona ensure that these innovations meet rigorous standards that ensure safe construction of durable roadways, this year and into the future.

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.

“Arizona’s blazing summer temperatures pose extreme challenges for concrete producers. Hot weather concreting can cause problems with placement, workability, and tends to affect the overall quality of the concrete. NITROcrete offers a solution to these obstacles delivering a more efficient process, reducing labor intensity and safety incidents, resulting in cost savings.”