Safer for people, safer for the environment with sustainable concrete.

- Sustainability necessitates controlling the variables of concrete production to mitigate waste

- Warming temperatures increase cooling demand; NITROcrete’s expertise in temperature control provides an alternative to ice cooling

- Using liquid nitrogen effectively requires comprehensive support

Hot weather, rising concerns

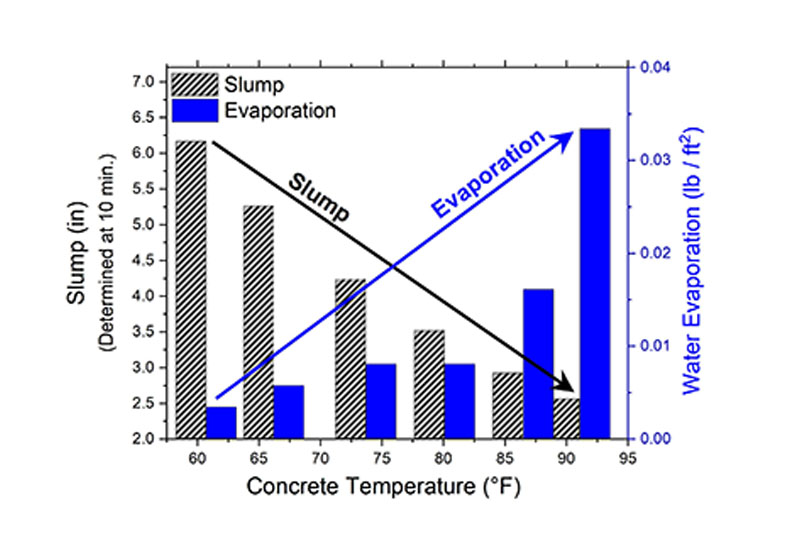

Hot weather concreting presents notoriously difficult problems for safe & sustainable construction — problems that the industry faces with warmer temperatures. Maintaining desired temperature during concrete batching, transportation, and curing is essential for safe, long-lasting concrete: good concrete. Good concrete that’s better for the environment and good for people. Good concrete that keeps bridges from collapsing & keeps dams from failing.

Additionally, corporations and the public alike demand more sustainable practices. With that, innovations that reduce waste and mitigate harm have gained industry traction and public attention in recent years.

How can the industry mitigate waste?

We know that sustainable concrete requires innovation and precision at each point of the production process. As industry partners step up, NITROcrete adds to their efforts by challenging the ubiquity of ice for temperature control.

Bags upon polythene bags and truckloads upon truckloads of ice. Miles of emissions and gallons of freshwater, for the sole purpose of decreasing concrete mix temperatures to meet specifications.

These specifications are, however, crucial for the long-term viability of concrete. By increasing performance at any point in production, concrete stands a better chance at avoiding waste.

This waste can occur when loads don’t meet site specifications for temperature, among other issues. Controlling temperature, therefore, becomes essential for both near-term and future concerns.

Environmental Implications

According to a third party report from John Beath Environmental (JBE) in 2019, “Besides the positive impact of concrete performance and the operation efficiency, NITROcrete also has environmental benefits compared with conventional ice cooling systems.”

To be clear: it is the comprehensive NITROcrete approach that provides the environmental advantages, not merely the addition of LN. This isn’t a “put turmeric in your coffee for better gut health,” or some other B.S. equivalent for sustainable concrete — you can’t just spray liquid nitrogen on aggregate and call it “green”. Instead, according to JBE, NITROcrete affords significant upstream and downstream environmental benefits. More control over cooling can allow the industry to mitigate waste and reduce emissions.

“NITROcrete performs better for relevant impact categories like energy usage, global warming, and respiratory effects in humans,” notes the JBE report.

What does precision control mean for sustainability?

Liquid nitrogen (LN) is not new to concrete cooling; however, until recently LN remained impractical — both economically and logistically. Creating dependable results requires precision dosage and reliable supply chains.

Now, with the right calibrations, “there’s reduced cracking, improved slump retention, and better workability. Plus, a command center that addresses issues in real-time,” says Eric VanDixhorn, Vice President of Engineering.

NITROcrete applies its industry expertise to supporting and training its customers. This partnership helps ensure desired performance. Ongoing support with tank-monitoring and supply chain logistics also help close the resource gap with automated software monitoring in the hands of expert support.

Sustainable Support

“Communication with customers from real people is key to our support,” says Jared Hall, Director of Software Engineering. “In order for those real people to help, we need real-time data to see what our customers need at-a-glance, whether it’s 2 am or in the middle of a critical pour,” Hall says. That real-time data helps prevent lost loads from supply chain issues. Hall began his career at the EPA where he developed software and maintained hardware for climate change research.

Besides obvious benefits to the bottom line, when operators can better anticipate variables like temperature, and have supplies delivered at reliable intervals, they can ensure that more loads meet specifications.

Safer Future

In addition to improving labor safety, NITROcrete joins the industry’s efforts to make concrete innovations work for now and work for the future. Every day, concrete paves the way to our jobs, undergirds the foundations of our homes, and manages our freshwater reserves. We’re all working hard to ensure that improving infrastructure now also results in a safer future.

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.

“Besides the positive impact of concrete performance and the operation efficiency, NITROcrete also has environmental benefits compared with conventional ice cooling systems.”