Automated Concrete Cooling Systems

Practical Liquid Nitrogen

For decades, the industry has experimented with liquid nitrogen (LN) to control concrete temperature. However, previous LN applications added complexity and cost. What’s different? NITROcrete™ operates differently by integrating with existing systems with ongoing support and sophisticated analytics.

- Streamlined process that cools while batching

- Supply chain management through comprehensive logistics support

- Controls that adjust dosage automatically, even as conditions change

NITROcretes Expertise

- Over 3 million yd3 / 2.3 million m3 of NITROcrete™ concrete used by major producers across North America

- Vetted by extensive third-party laboratory testing

- In use in over 160 sites across North America

- Collaborative approaches with numerous US Departments of Transportation

How NITROcrete

Automates Temperature Control

Liquid Nitrogen Dosage That Adapts While Batching

Method

By cooling during batching, NITROcrete simultaneously removes downtime and introduces temperature control that adapts to changing conditions. In this manner, liquid nitrogen is delivered similar to an admixture.

Results

Precision dosage of liquid nitrogen allows producers to automate and adapt liquid nitrogen delivery to account for variables like ambient temperature.

Application to Aggregate

Method

NITROcrete applies liquid nitrogen to the aggregate rather than the entire mix.

Results

By applying the liquid nitrogen directly to the aggregate, temperature control permeates the mix. Aggregate contributes the most heat to the batch by mass; therefore, lowering aggregate temperature more effectively cools the whole mix – without changing the water content.

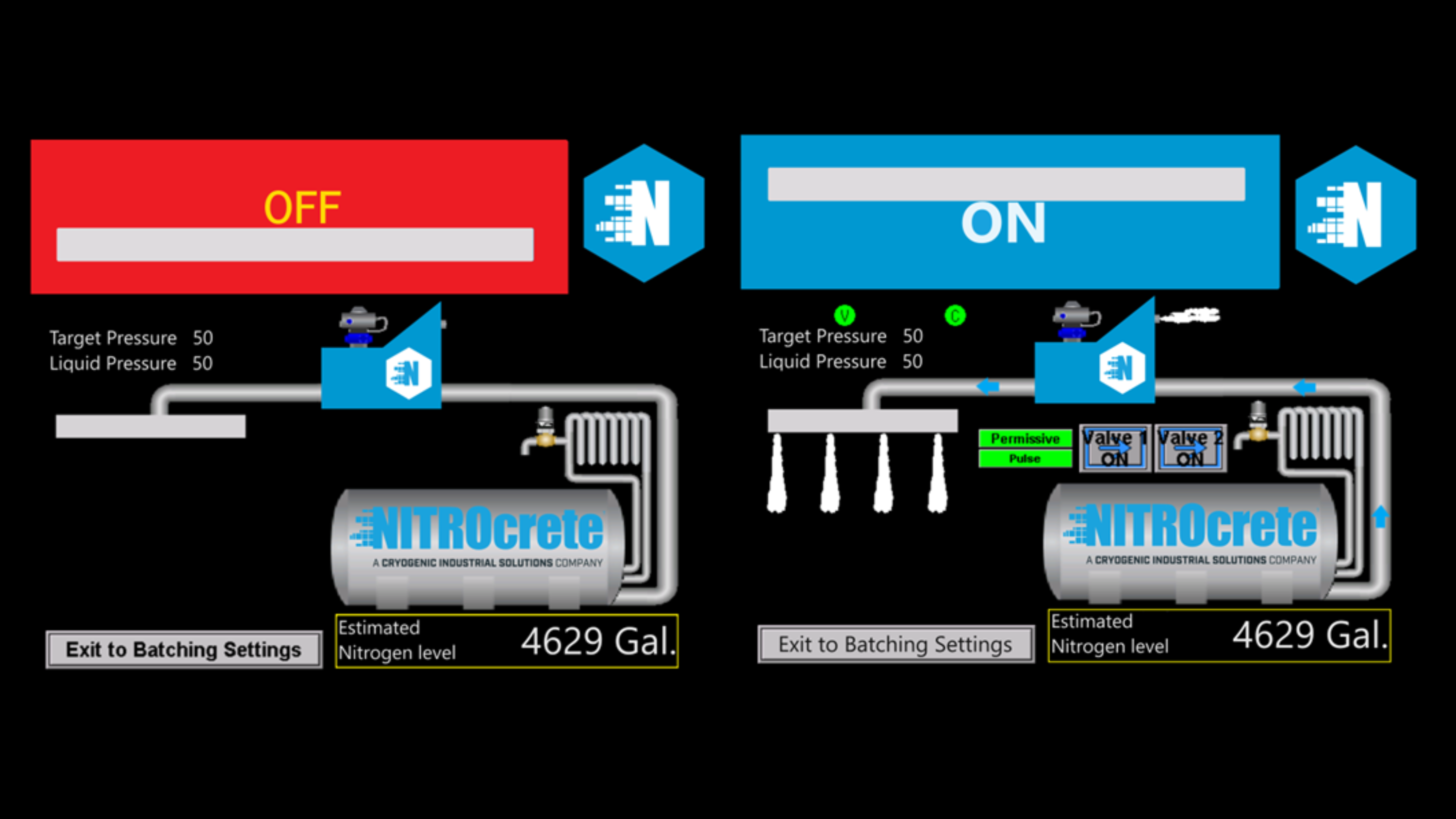

Cloud-Managed HMI & NITROvision Integration

Comprehensive Insight

The NITROvision automated system integrates with our onsite HMI to give producers more data and insight about their cooling processes. With greater awareness, NITROvision enables dependable, repeatable results for temperature control.

Reassurance & Telemetry

With a fully managed and automated system, our integrations allow tank-level monitoring and 24/7 support from analysts empowered with real-time information about conditions onsite. Telemetry enables remote awareness to monitor pressure, usage, equipment status, and run-ready capabilities.

Seamless Integration

Our software and HMI seamlessly integrate with all existing batching software brands. Integration supports wet or dry plants, 1-2 lane usage, and offers off-set & safety shut-down timers.

Ongoing Supply Chain Management

Planning and Analysis

With dosage and supply planning from NITROcrete’s dedicated analysts, we’ve solved the complicated logistics of liquid nitrogen delivery and planning. We streamline logistics with gas supply vendors and monitor dispatch status to ensure everything remains on schedule.

24/7 Monitoring

Our technical support analysts monitor performance daily. They perform routine health checks to ensure systems stay optimized for the desired temperature control. Automated alerts empower our team to provide quality support promptly.

Seamless Integration

Automate the supply chain with expert planning from our analysts. NITROfill enables cloud-based data to trigger liquid nitrogen ordering on the desired schedule. With automated supply monitoring, we offer another level of ease for temperature control.