Finishability and Concrete Cooling

Quantifying the Perfect Spring Day for Concrete Construction

Imagine an 84°F (29°C) day in Atlanta, Georgia. While some might call that a “cold front” late summer, it’s June. You wipe sweat from your brow and recall how long summer in Georgia lasts. It’s a long day of work, and a long summer ahead.

But today, you notice that something’s different. The fight isn’t there — the concrete is actually easy to finish. You put your head down and keep working. You can’t recall a summer day when finishing work was this easy.

Quantifying “Easy Finishability”

We often hear from project foremen and contractors that NITROcrete makes concrete easier to place, consolidate, and finish. They share that crews and equipment don’t have to fight slump loss and poor workability. We’ve heard them say “it’s easy springtime concrete, but in the middle of summer.” Contractors and finishers practically wax poetic about that perfect concrete day, either in spring or fall. A day when the ambient temperature, wind velocity, and humidity all create the ideal conditions for easy concrete construction.

Pouring concrete in July as if it were April is great news for concrete construction, but challenging for R&D to quantify beyond the growing number of enthusiastic customer stories.

Beyond anecdotal evidence, we wanted to understand how cooling concrete aggregates with liquid nitrogen makes finishing concrete easier. Specifically, we wanted to mitigate the impact of human variables to more accurately quantify the stories we’d heard about.

We first set about measuring workability and slump. While common practice would suggest a natural relationship between finishability and slump, no industry-accepted method exists to quantify finishability, the ease of concrete finishing work.

Advanced rheology 1 methods do offer explanations. We drew from the existing body of rheological research to inform how we developed our methods and understood our conclusions. For instance, a “squeeze-flow” test could allow us to evaluate rheological properties; in such tests, cement pastes and aggregates are compressed to simulate the way cement and aggregates are squeezed during concrete finishing. Then, we’d measure the extrusion force, which we could then relate to concrete finishability. Currently, this testing method is out of our research’s scope; however, NITROcrete plans to further investigate this method for future testing.

Initial Defining and Testing for Finishability

We use “finishability” here as a measurement of how difficult it is to “finish” concrete once it has been placed. AC302.1R-15 specifies a window of finishability “time period available for finishing operations after the concrete has been placed, consolidated, and struck-off, and before final troweling” (ACI 302.1R-15) In other words, a window of finishability starts a clock ticking on when and for how long laborers can adequately and easily finish the concrete; therefore, teams often have to work quickly (or use more labor) to finish concrete well. Because of this, easier finishability helps projects stay within the desired window of finishability.

Measuring Finishability

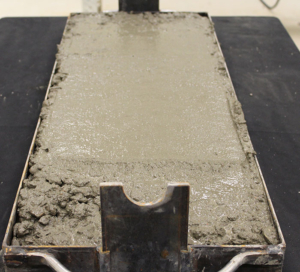

Based on previous research, we derived a method to help quantify the ease of finishability. This method compares the temperature and slump to the required number of passes (a measurement we define as the “finishability index”2). For the test, we placed concrete in a form similar to testing protocols described in ASTM C78 / C78M – 18, with the exception of finishing the surface with a trowel.

Figure 1: Concrete in testing form

Next, we finished the concrete with a float designed to apply the same pressure, angle, and motion to the fresh concrete with each pass. We designed the float and form to mitigate human influence — so that each pass was as consistent as possible, while still replicating similar motions used in finishing concrete onsite. We then recorded the number of passes required to finish the concrete as the finishability index.

For this test, we considered concrete “finished” when all visible pores and voids in the surface were closed up, and when we noticed no noticeable difference in the surface between the previous pass with the float. During the test, we recorded video3 of the process to verify the finishability index through image analysis. More on this analysis in a future article.

We tested an uncooled batch of concrete as a control, then cooled subsequent batches to various temperatures (see figure 2 below). The concrete was batched according to ASTM C192 protocols for sampling and mixing.

Figure 2: Concrete in form after finishing

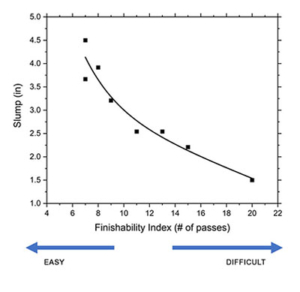

From the results reflected in the charts below, we found a clear correlation between concrete temperature and finishability.

As our previous workability research showed, temperature affects concrete slump, and therefore finishability. As temperature increases, slump loss and finishability index increase, which makes higher temperature concrete harder to work with and more difficult to finish.

Figure 3: Slump and Finishability

From Figure 3, we can directly relate concrete slump and finishability. As slump decreases (typically indicative of lower concrete temperature), fewer passes are required to finish the concrete.

Figure 4: Temperature and Finishability Index

The data above in Figure 4 shows the number of passes required to finish concrete batches at various temperatures. The 90°F (32°C) batch took 20 passes to finish, while the liquid nitrogen-cooled batches that measured between 60–70°F (15.5–21°C) took 7-8 passes to finish.

Implications

Our research corroborates what we’ve heard from our customers and their customers: Cooling aggregates with liquid nitrogen prior to batching makes finishability easier, meaning less “fight” with the concrete to achieve a finished state.

Concrete that’s easier to finish reduces time and labor strain. This ease cuts down on finishing time and effort could also improve schedule compliance for potential time- and cost-savings for concrete construction.

Also significant here: finishing occurred without adding excess water to the concrete mixture. Without adding water, we reduce the likelihood of plastic shrinkage cracking, scaling and spalling, and other durability and serviceability issues.

Conclusion

With fewer passes, concrete cooled with liquid nitrogen using NITROcrete’s system took fewer passes to finish the concrete. The uncooled batches (90°F / 32 °C) required over twice the number of passes as the liquid nitrogen cooled concrete batches.

This research is ongoing, and we look forward to sharing more results as we learn more. In the meantime, we’re grateful to have a clearer understanding of the stories we hear about NITROcrete concrete’s ease of finishability every summer.

Footnotes

1. Branch of physics concerned with flowable matter; for example, fresh concrete

2. The finishability index quantified the number of passes required to finish the concrete, a process we illustrate in the video excerpt.

3. Astute readers may note different testing apparati in the video and the photographs; an earlier version of the test apparatus appears in the video–in further testing, we updated the apparatus to the photographed form here.

Summary

- Comments in the field about ‘easy finishing’ struck our curiosity

- No approved method exists to quantify finishability

- So, we devised a way to discover the ‘finishability index’

- Uncooled concrete requires 20 passes to finish

- NITROcrete cooled concrete required only 7 passes

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a sustainable concrete cooling solution, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.