Concrete Cooling System Manufacturer

The Liquid Nitrogen Solution for Concrete Temperature Control

Redefine Achievable

NITROcrete aims to enhance the lives of those building our communities. Partnering with industry leaders, we improve safety, profitability, and sustainability. As the concrete industry innovates, NITROcrete modernizes concrete cooling for the 21st century.

GET IN CONTACTWhat we do for you

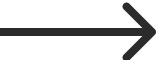

Automate Cooling

Cool concrete efficiently using liquid nitrogen with advanced concrete technology. Automated batching ensures consistent cooling, even in hot weather.

Speed-Up Production

Automation boosts production and cuts pour time without sacrificing quality, reducing project duration by days or weeks.

Enhance Saftey

Delivering liquid nitrogen as an admixture, NITROcrete enhances worker safety by eliminating ice cooling. This method increases reliability while reducing strain and hassle.

As a concrete cooling system manufacturer, NITROcrete automates temperature control for simpler, more reliable concrete cooling. As world leaders in temperature control, we support

the industry with cutting-edge technology

and dependable support.

Automates cooling to achieve lower temperatures without downtime or labor strain. Automated cooling informed by data analysis, precision dosing, and seamless integration with existing systems.

GET A QUOTESustainability in concrete control

With the confidence of temperature control, our customers build for the future.

They build with durable concrete and reduce waste.

Reduce carbon emissions

NITROcrete reduced CO2 emissions by 83% when compared to conventional ice cooling in a third party life cycle analysis report.

Avoid Waste

By meeting temperature specification, concrete avoids wasted loads, thereby avoiding the subsequent energy waste during production.

Low Energy Consumption

With a more streamlined process, NITROcrete means a 66% reduction in energy usage when compared to conventional ice cooling.

Curtail particulate matter

Compared with conventional ice cooling, NITROcrete™ produces 87% less particulate matter.

Eliminate polythene bags

Without the need for thousands of ice bags for cooling, liquid nitrogen eliminates polythene bag waste from ice.

Prevent injury

NITROcrete plays a crucial roll in our industry partners’ comprehensive plans as a mass concrete cooling system supplier; to reduce strain on labor and to make work safer and easier

Project Profiles

Toronto

Mass concrete and high performance mix design on CIBC Towers

Atlanta Mass Concrete

Speeding Up Production Rates

Harbor Bridge

Six-figure savings by eliminating cooling tubes.

I-74 Mississippi Bridge

Lower temperature delivered over 36+ hour pours

Seattle

Traffic threatened to stall

a 950-yard-pourix design on CIBC Towers

Atlanta

Finishers noted the cooling

was noticeable through

their work boots.

Latest News

Collaboration with Wisconsin DOT for Ongoing Specification Development

When the Wisconsin Department of Transportation sought lower temperature specifcations for concrete road work, concrete cooling with liquid nitrogen caught...

Read More >

Cryogenic Industrial Solutions acquires NITROcrete, expanding offerings with new technology

Cryogenic Industrial Solutions (CIS), a leading provider of cryogenic transport trailers, tanks, equipment repairs, lease fleet and nitrogen services, announced...

Read More >

ADOT changes specification to include liquid nitrogen

“We often receive questions about the effects of liquid nitrogen on aggregates,” said Eric Van Dixhorn, NITROcrete VP of Engineering....

Read More >

VDOT Approves NITROcrete

After about a year of testing, NITROcrete is now approved by the Virginia Department of Transportation for safe use in...

Read More >